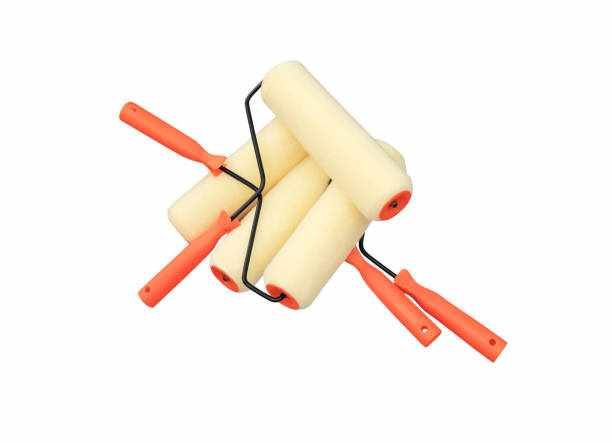

Paint roller covers, especially the 4 inch paint roller covers, are essential tools for achieving smooth and even finishes in painting projects. Professionals and do-it-yourselfers love these adaptable covers since they are ideal for smaller surfaces, trim work, and other accuracy chores. Still, their efficacy mostly depends on good maintenance and care. Extended roller cover lifetime not only helps you save money but also guarantees continually excellent outcomes.

Understanding the Structure of Paint Roller Covers

Understanding the construction of 4-inch paint roller covers helps one better appreciate maintenance recommendations. Usually composed of polyester, microfiber, or foam, these covers are Every material has different qualities; polyester is perfect for general use; microfiber shines in smooth finishes; foam is the finest roller for epoxy applications since it helps to prevent streaks and bubbles. Understanding the content of your roller cover can help you choose appropriate cleaning and storing techniques.

Cleaning Your Roller Covers Immediately After Use

One of the most important actions in prolonging the life of your 4-inch paint roller covers is a quick and thorough cleaning. Rinse the roller cover under running water to get extra paint off as soon as you finish painting. For water-based paints, gently scrub the fibres using warm water and mild soap.

Regarding oil-based paints, one will need a solvent such as paint thinner or mineral spirits. To guard your hands from strong chemicals, be sure you don gloves. Once cleaned, shake off the extra water and let the cover dry totally in a well-ventilated place to stop mould growth.

Avoiding Common Cleaning Mistakes

Many consumers make blunders throughout the cleaning process that may greatly shorten the lifetime of their roller coverings. Using too strong brushes or washing too aggressively, for example, can damage the fibres and cause unequal application in the next jobs. In the same vein, is nearly hard to clean successfully when the paint dries on the roller cover. To keep your 4-inch paint roller covers integrity, always clean them right away using mild but powerful cleaning equipment.

Storing Your Roller Covers Correctly

Maintaining the lifetime of your roller coverings depends on proper storage as much as cleaning. Store your 4-inch paint roller covers in a sealed plastic bag or container once cleaned and dried to maintain them dust-free and ready for use. To keep the same roller cover from drying out if you want to use it in a day or two, put it in plastic wrap or an airtight bag. When handling specialty applications, such as epoxy paints, where the ideal roller for epoxy needs to be in perfect condition for maximum results, this method is extremely helpful.

Rotating Roller Covers During Larger Projects

Rotating between many roller coverings makes sense for large painting operations. This method evenly distributes the labour and lets a single roller avoid too much wear. Alternating two or more 4-inch paint roller covers guarantees consistent performance and lets each cover have opportunity to retain shape and absorbency. Using rollers with sensitive materials like foam, which can wear out more quickly if overused, this technique is very helpful.

Choosing High-Quality Roller Covers

The original quality of your roller coverings will usually determine their lifetime. Purchasing robust, well-made 4-inch paint rollers guarantees their ability to resist frequent usage and cleaning. Look for covers with strong foam constructions or tightly spun fibres since these are less likely to shed and distort. Choosing the ideal roller for epoxy jobs, including foam rollers meant to stop streaking, will also help to improve your painting results and prolong the life of your tools.

Regular Inspection and Replacement

Roller coverings will wear out finally even with the finest of treatment. Check your 4-inch paint roller covers often for deterioration like flattened areas, frayed fibres, or residual paint accumulation impossible to remove. Using a worn-out roller cover can waste paint and provide uneven results. Quick replacement of outdated or damaged rollers guarantees that your painting jobs stay professional-looking and smooth. Keep several extra roller coverings handy to prevent disruptions throughout your work.

Adopting Best Practices for Specialized Paints

Some paints, such as high-gloss finishes or epoxy, call for specific treatment. Working with these materials, utilize the best roller for epoxy to get a perfect finish. These uses benefit especially from foam rollers since they reduce the appearance of bubbles and streaks. Clean the roller right away after use to avoid the paint hardening and sacrificing its quality. Following these best standards not only prolongs the lifetime of your roller covers but also ensures outstanding performance in tough projects.

Conclusion: A Small Effort for Big Savings

Although it seems like a small chore, maintaining appropriate maintenance for your 4-inch paint roller covers significantly affects your painting efficiency and cost. Understanding the materials, cleaning right away after use, avoiding common mistakes, and properly storing them can help you extend your lifetime and preserve great results. Whether your project is small-scale do-it-yourself or professional, the performance and lifespan of your roller coverings make all the difference. Using the appropriate roller for epoxy paints, for instance, guarantees both efficiency and quality when handling specialist applications. These guidelines will help your painting tools remain in great shape and be ready to produce flawless results every time.

Write a comment ...