When it involves coating large surfaces with epoxy, performance and precision are everything. Whether you are renovating a industrial warehouse, sealing a storage floor, or applying an epoxy machine to a retail space, your choice of software gear will make or smash your consequences. For professionals and extreme DIYers alike, the 18 inch epoxy roller has emerged as a pass-to tool for epoxy flooring projects—handing over velocity, smoothness, and consistency on a scale that trendy rollers can’t in shape.

But what makes an 18-inch epoxy roller the perfect preference for these tasks? And how are you going to make certain you’re choosing the right type, fabric, and nap for epoxy use?

In this comprehensive manual, we’ll dive deep into what makes an 18 inch epoxy roller so powerful, while and how to use it, what to search for whilst buying, and what errors to avoid. By the end of this post, you may have a clear understanding of a way to get a ideal end—and the way the right roller could make a international of distinction on your epoxy floors assignment.

What Is an 18 Inch Epoxy Roller?

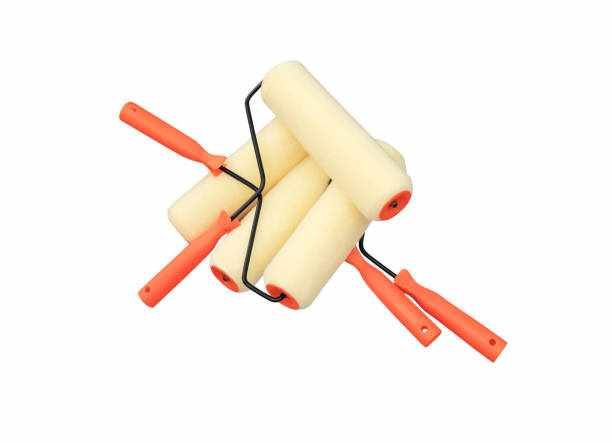

An 18 inch epoxy roller is a huge-layout roller designed in particular for applying epoxy and different heavy-obligation coatings across massive floor regions. It uses a roller body that comprises a curler cover 18 inches in period—double the dimensions of the usual 9-inch roller.

Unlike everyday rollers, which might be regularly used for partitions or small rooms, the 18-inch variation is designed to maximise productiveness and make sure uniform insurance. It substantially reduces the number of strokes needed, helping preserve a moist side and putting off lap marks—a commonplace problem with fast-drying epoxy paints.

When paired with the right frame and extension pole, this roller is ideal for:

Garage floors

Basements

Warehouses

Showrooms

Commercial kitchens

Workshops

Benefits of Using an 18 Inch Epoxy Roller

1. Faster Application Over Large Areas

The maximum apparent benefit is pace.

An 18-inch roller lets in you to cover greater ground in less time.

This is important with epoxy as it has a constrained pot lifestyles (the window of time you need to work earlier than it begins to harden).

2. Even Coverage and Consistency

Epoxy coatings are known for their sleek, expert appearance—but only in the event that they’re carried out evenly.

A first rate 18-inch roller distributes the epoxy evenly across the floor, minimizing the threat of air bubbles or pooling.

3. Maintains a Wet Edge

Keeping a wet aspect in the course of utility is key for a unbroken finish.

The roller covers greater area in a single bypass, making it less difficult to work faster and avoid dry strains or overlapping errors.

4. Less Fatigue

With fewer again-and-forth strokes, an 18-inch roller can substantially lessen bodily strain.

5. Professional-Grade Finish

Contractors often use 18-inch rollers for commercial jobs because they could produce clean, constant effects quick.

Choosing the Right 18 Inch Epoxy Roller

Not all 18-inch rollers are created identical. The first-class of your curler cowl and its compatibility with epoxy coatings will decide the achievement of your undertaking.

1. Roller Material

The cloth must be long lasting and resistant to epoxy’s chemical additives. The pleasant options encompass:

Microfiber: Excellent for reaching a easy end. It holds just the proper amount of epoxy and releases it calmly.

Mohair: Lint-free and perfect for excessive-gloss finishes.

Woven Synthetic (Nylon/Polyester blends): Durable, solvent-resistant, and correct for heavy-responsibility industrial epoxy programs.

Avoid foam rollers for epoxy—at the same time as beneficial for some finishes, they often trap air, causing bubbles in epoxy.

2. Nap Length

Choosing the correct nap is crucial primarily based on the surface texture and the type of epoxy being implemented.

¼” Nap – Best for smooth surfaces like concrete floors.

⅜” Nap – Slightly more absorbent and works on lightly textured surfaces.

½” Nap or greater – Useful for textured concrete or older, rougher surfaces.

For most residential or commercial epoxy flooring tasks, a ¼” to ⅜” nap is considered optimal.

3. Shed Resistance

Lint is your enemy whilst making use of epoxy.

Always go for shed-resistant or lint-free rollers, particularly microfiber or mohair.

4. Core Construction

Ensure the curler has a solvent-resistant plastic or phenolic resin center.

Epoxy resins and solvents can ruin down cheap cardboard cores.

5. Frame Compatibility

Make certain the curler cowl fits securely on an 18 inch epoxy roller designed for epoxy use.

Step-by-Step: How to Use an 18 Inch Epoxy Roller

Even the fine curler gained’t supply exact consequences with out the proper technique.

Step 1: Surface Preparation

Clean the surface thoroughly. Remove grease, dirt, and dirt.

Etch or grind concrete to open the pores and make sure better adhesion.

Fill cracks or divots with epoxy filler.

Step 2: Mix Epoxy Correctly

Follow the instructions for your epoxy product exactly.

Mix components A and B the use of a drill mixer for the advocated time.

Pour into a roller tray or immediately onto the floor relying on method.

Step 3: Load the Roller

Roll the 18-inch cover inside the tray till absolutely saturated.

Avoid overloading to reduce dripping or choppy application.

Step 4: Roll with Precision

Start on the farthest nook and paintings backward in the direction of the go out.

Use a “W” or zig-zag sample to spread the epoxy, then backroll in a single path to smooth it out.

Maintain a wet part through running in sections and overlapping barely.

Step 5: Allow to Cure

Don’t walk on the ground until the epoxy has cured in keeping with the manufacturer’s instructions.

Avoid dust or airflow which can intervene with curing.

Common Mistakes to Avoid

Using a roller with too thick a snooze – This can result in texture where none is needed.

Applying epoxy too thickly – Leads to puddling or sluggish curing.

Using a non-epoxy-rated roller – May shed or degrade in touch with the chemicals.

Not prepping the surface – Causes negative adhesion and peeling.

Working too slowly – Epoxy sets rapid. The wider curler enables, but you must live ahead of the therapy.

Tips for Maintenance and Reuse

Clean right away: Use acetone or the advocated purifier right after use.

Don’t postpone: Epoxy hardens fast—rollers must be wiped clean or discarded straight away after use.

Use extremely good gadget: A desirable 18-inch body and extension cope with may be reused for years.

While maximum epoxy rollers are considered disposable, premium-quality covers can occasionally be reused if cleaned promptly and thoroughly.

When to Use Brushes Instead of Rollers

Although the 18 inch epoxy roller is unrivaled for insurance and velocity, there are moments when a brush is important:

Edge paintings: Cut in round walls, furniture, or drains with a broom earlier than rolling the principle place.

Detail areas: Use brushes for corners or around barriers.

A herbal bristle paintbrush is perfect for those jobs. Natural bristles paintings in particular nicely with solvent-based epoxies and offer brilliant control for high-quality detail or touch-ups.

In Conclusion: Best Roller for Epoxy Floor

For best roller for epoxy floor projects, there is no better tool than an 18 inch epoxy roller. It gives:

Rapid, even coverage

Smooth, professional finishes

Reduced attempt and fatigue

Better consequences in less time

But don't forget—your curler is simply one part of the equation. Choosing the proper nap, fabric, and center construction ensures compatibility with epoxy products and stops expensive errors.

And whilst the 18 inch epoxy roller the majority of the paintings, don’t forget the importance of detail. For edges, corners, and difficult regions, a herbal bristle paintbrush is the correct accomplice for your roller setup. It permits for unique control and perfect mixing, specially where rollers can’t reach.

Whether you’re a seasoned painter or an bold DIYer, investing inside the proper tools—beginning with the great curler for epoxy ground—makes all of the distinction among an average task and a staggering, showroom-pleasant result.

Write a comment ...